|

MOULD

DESIGN AND MAKING |

|

|

|

|

UnionMould

believe mould quality begins with

mould design and consider it to the key of successful mold making.

From start to end, the mould design will be handled by a PM who is

appointed to your projects. We will assure all mould designed as per

client mould data request and all the information we discussed in

emails, then mould manufactured as per the approved drawings by clients. |

|

|

|

|

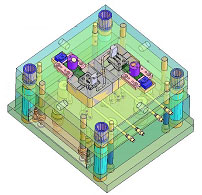

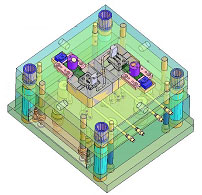

Mould design

At

UnionMould,

the mould's Designer and Engineers personnel have profuse mould/part

design experience and fluent software operation ability. They can show

the mould structure and client expectations clearly in 2d and 3d mould

drawings.

Combined with the latest versions of AutoCAD™ ,Pro/E™

,UG and

Solidworks™ for design and Mastercam™,UG

for

manufacture (with the ability to accept files from any other design

software) ----and our interactive design approach, we have the

capabilities to get your project from concept to practice in

shortest amount of time possibly.

|

|

|

|

|

|

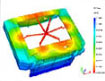

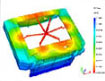

For those products with complicated structure, we

will use CAE software to make flowing analysis to ensure the

possibilities of good injection. The mould design will be submitted to

customer in a couple of days to get approval and comments. Update

will be finished promptly as per the comments from customer .

We guarantee strictly the mold making

under the confirmed drawings. |

|

|

|

|

Mould making

We have advanced mould

making equipment (such as CNC machine, EDM machine, Grinding

Machine, Milling Machine and Wire cutting machine etc). These

equipments will be the precondition of making good mould.

In addition, our mould makers have years of

experience in mould making. The

abundant

experiences do much help to avoid the mistake in the

making process and to make complicated moulds for ensuring the

quality of the mould at the same time.

All the moulds are

made under the guide of client approved mould drawing.

All the moulds are made as per the client specification, Except the

simple 2 plate and 3 plate standard mould, we have much

experience in hot-runner mould

,insert mould, etc. . The

high expensive Hasco and DME tools are also acceptable under our

ability. The hot runner system band we used

are as following: Hasco, DME, Husky, Yudo, MasterTip etc.

Customer

satisfaction is our top priority.

Time process schedule will provided in couple days after we get the

tools approval. Weekly status report will also supplied to clarify

the mould weekly status.

|

|

|

|

|

|

|

Mould debugging

After finish making the tools, we have a system process

to

test the tools structure and the mould

capability. Each time of test will get a record of the injection machine,

water control machine and the other relative device. We will get an

optimization injection condition to suggest client before shipping the

tools.

|

|

| |

|

Mould steel

Our mould based on the world famous

standard moldbase and components of LKM, for easy order and guarantee the

short leedtime. Many kinds of world-wide applied mould steels are

most adopted in our tools, such as 718, 738, S136 from ASSAB

of Sweden, NAK80 from DAIDO of Japan,and the stainless

steel and S7,D1,01.....high hardness steel. At the same time, we can design mould according to

the customer's

requirement, such as DME, HASCO. |

|

|